Fire Extinguishers That Do Not Corrode – Everything You Need To Know for the Aviation Industry

Every industry requires a fire safety strategy that’s tailored to its exact requirements. In some industries, such as aviation, the approach must be even more regulated and assessed, as the consequences of a fire breaking out are that bit more serious.

Every industry requires a fire safety strategy that’s tailored to its exact requirements. In some industries, such as aviation, the approach must be even more regulated and assessed, as the consequences of a fire breaking out are that bit more serious.

One of the key aspects of the fire safety setup is the fire-fighting equipment that is required in each particular scenario, and on board aircraft this means attention must be paid to the fire extinguishers present.

Corrosive and Non-Corrosive Fire Extinguishers

In industries that rely on the operational ability of electrical equipment, it is important to ensure that the flame extinguishing agent contained in the fire extinguisher is non-corrosive in nature.

- Immediately, this discounts dry powder extinguishers, as even if the area is thoroughly cleaned after coming into contact with this extinguishing agent, a mildly corrosive effect can still occur (particularly if there is any hint of moisture).

- CO2 extinguishers may be more suitable in this respect, and are sometimes used in computer rooms to remove fire by starving it of oxygen.

- Water units should be avoided due to its lack of flexibility with class B, C and electrical fires, and excessive moisture can cause rust and other corrosive damage to some metals.

- Other popular types, including foam and wet chemical extinguishers, may be appropriate depending on the environment in which they are utilised, but will need extensive cleaning following their use.

- Halon extinguishers are highly flexible for use on all class A, B and C fires, and their non-corrosive and non-conductive chemical makeup makes them ideal for aircraft usage (see below for more).

FAA & CAA Aircraft Fire Safety

A recent joint campaign by the UK Civil Aviation Authority (CAA) and the US Federal Aviation Administration (FAA) has highlighted specific fire risks on board all aircraft, reporting on common causes (unstable electrics, dust gathering in ventilation areas etc.) as well as emphasising the importance of fire safety training.

The initiative focuses on particular areas of the aircraft which may be inaccessible to the cabin crew while airborne, where a blaze may go undetected for a considerable amount of time. Statistics show that in-flight fires that become unmanageable will lead to a loss of control of the aircraft within 15 minutes on average.

An important part of staff health and safety training for all aircraft cabin crew revolves around fire extinguisher awareness and use.

Fire Extinguishers for Aircrafts

One of the key considerations when ensuring that the correct fire extinguishers are used in various parts of the aviation industry is whether or not the extinguishing agent is corrosive to metals, such as aluminium.

In the majority of cases, this rules out the use of dry powder extinguishers, as the chemical makeup of the agent can cause some degree of corrosion – particularly monoammonium phosphate, which forms phosphoric acidic where others are solely alkaline.

Indeed, in a service letter written by Boeing in 2005, it was stated that “Dry chemical extinguishers can cause extensive corrosion damage to airplane structure, electrical systems, and electronic equipment. Dry chemical extinguisher residue is difficult to clean up. Dry chemical fire extinguishers should only be used for airplane firefighting if there are no other extinguishers available and there is imminent danger to property or personnel.”

Similarly, while carbon dioxide extinguishers are not considered corrosive as such, they can cause damage to electrical components in other ways (cold-shock), as well as potentially reducing oxygen levels in the cabin. Water should never be used due to its fundamental incompatibility with electrical current.

Both the FAA and the CAA suggest that ‘Halon’ extinguishers are best in an aircraft environment. Short for ‘halogenated hydrocarbon’, these extinguishers contain a mix of carbon, fluorine, chlorine and bromine in various denominations in a liquefied gas. The four digit number after each name displays the number of atoms of each element present in the Halon agent. Only Halon 1211 and Halon 1301 (or a combination of the two) are permitted.

Not only is Halon non-corrosive, it also leaves no sedimentary deposits that might block ventilation systems or electrical components. Its chemical makeup is suitable for human exposure, and, unlike carbon dioxide, it doesn’t extinguish fire by displacing oxygen from the surrounding air.

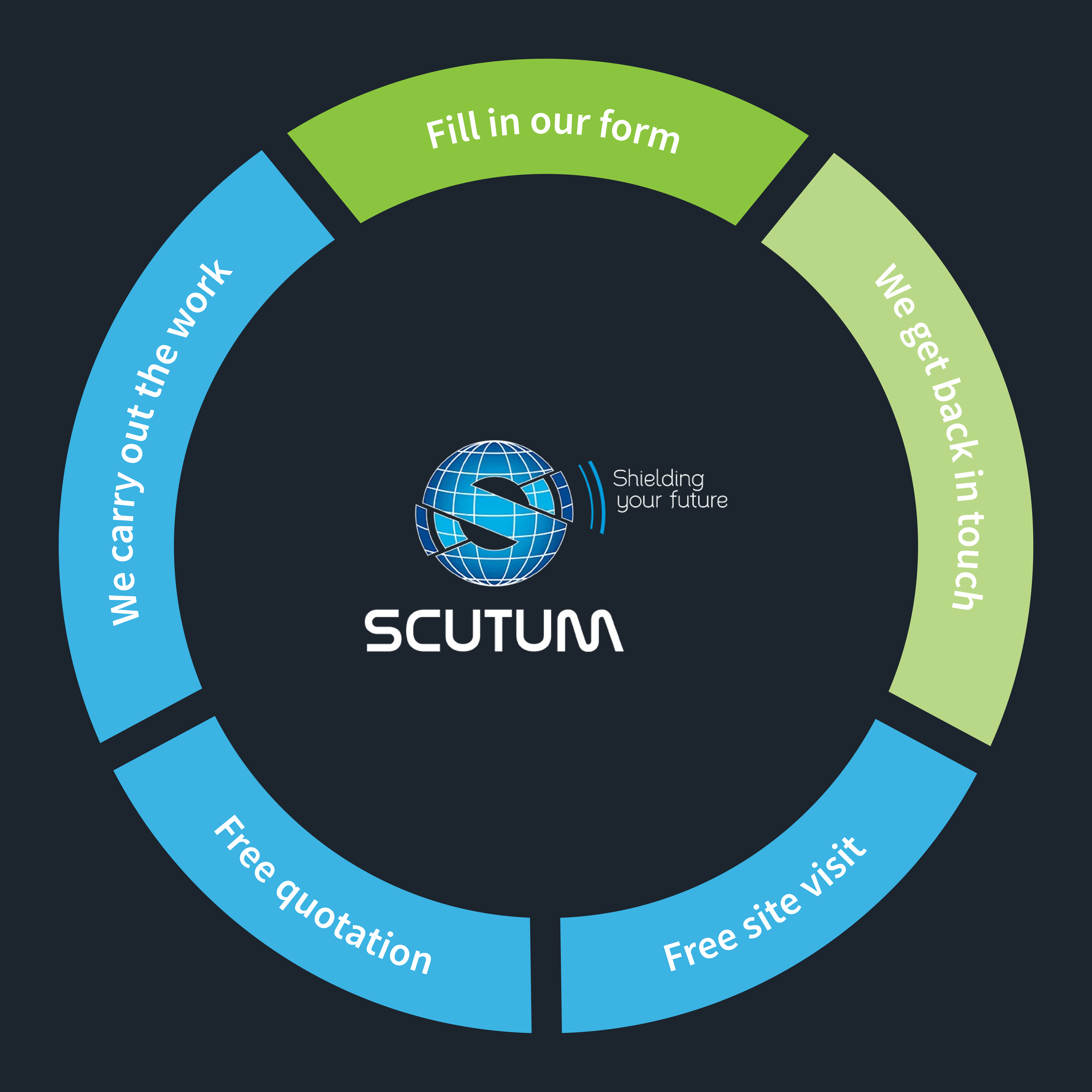

Request a Callback

Just fill in your details below and we'll get back to you as soon as we can!

About Scutum London

Scutum London is a leading expert in fire safety and security solutions for businesses and organisations located across South East England, including London and Surrey.

From fire alarms, fire extinguishers and fire risk assessments to access control, CCTV and intruder alarm systems – and a lot more besides – we offer a comprehensive range of products and services designed to keep you, your business and your staff and visitors safe.

With decades of industry experience to call on, we’re proud to hold accreditations from leading trade associations and bodies such as British Approvals for Fire Equipment (BAFE), the British Fire Consortium, the Fire Industry Association (FIA) and Security Systems and Alarms Inspection Board (SSAIB).

If you’d like to find out more about Scutum London, get in touch with our friendly team or explore our products and services on our site.